I thought I would be smart and save some money and get a used tiller for the garden. Instead what I did was buy some scrap metal, then spend more time and money to turn it back into a tiller. The guy that was selling it described it as a “bad bearing”; I bet he was laughing as soon as I left. Luckily it was cheap.

To be fair to the guy, it did have a bad bearing… in the exploded gearbox. It had clearly been apart, so no doubt he knew what was up.

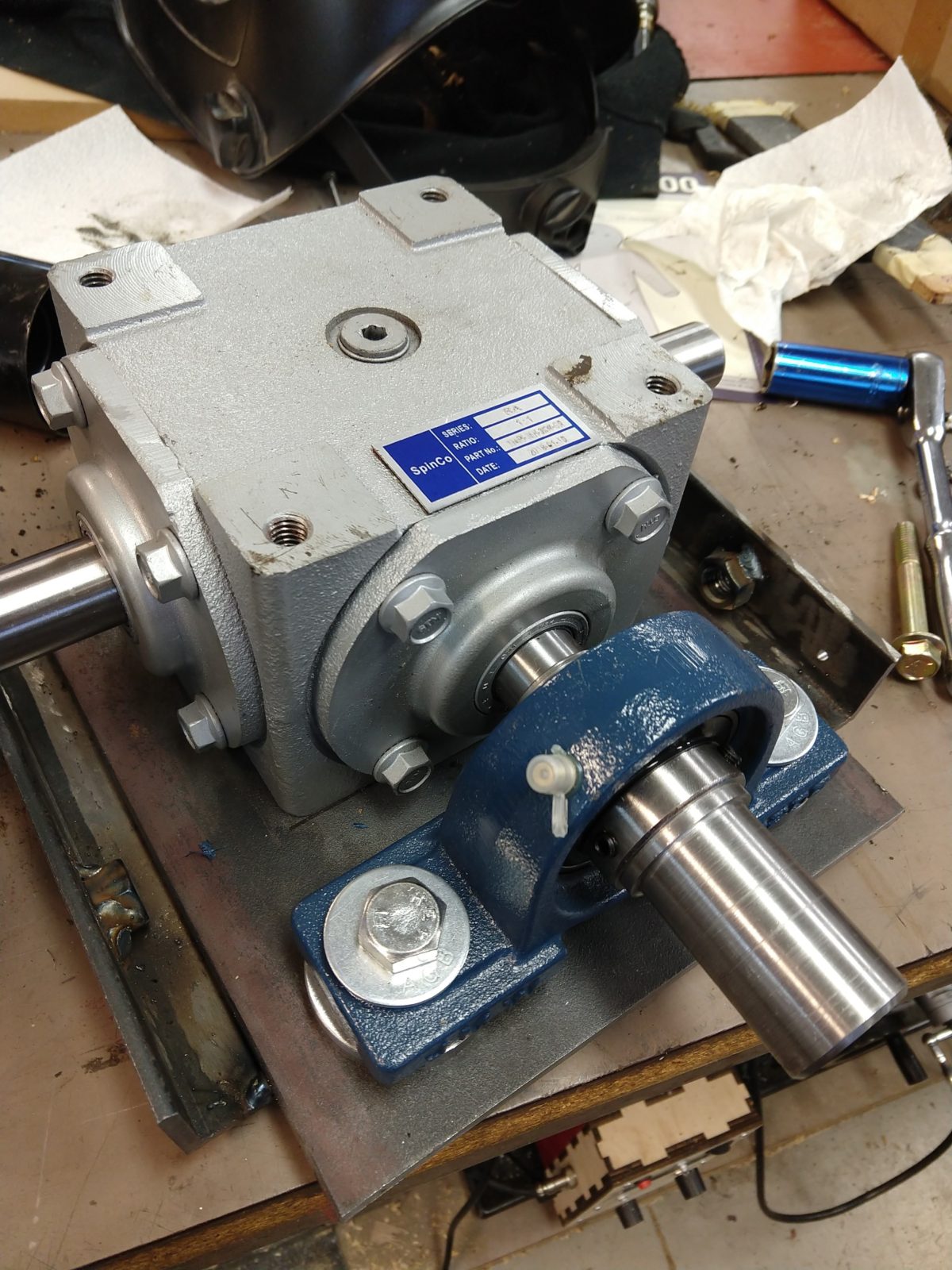

How do you fix that? This is a 40-series from the ’70’s, most parts are unavailable, and even worse, the shaft connecting the chains on the ends to the gearbox in the center is one solid piece. In order to disassemble it I would have to press that shaft almost three feet through the box to get it out. My answer was to replace the whole thing with the cheapest gearbox from China I could find on Ebay and adapt it to work in it’s place.

Here’s what I did:

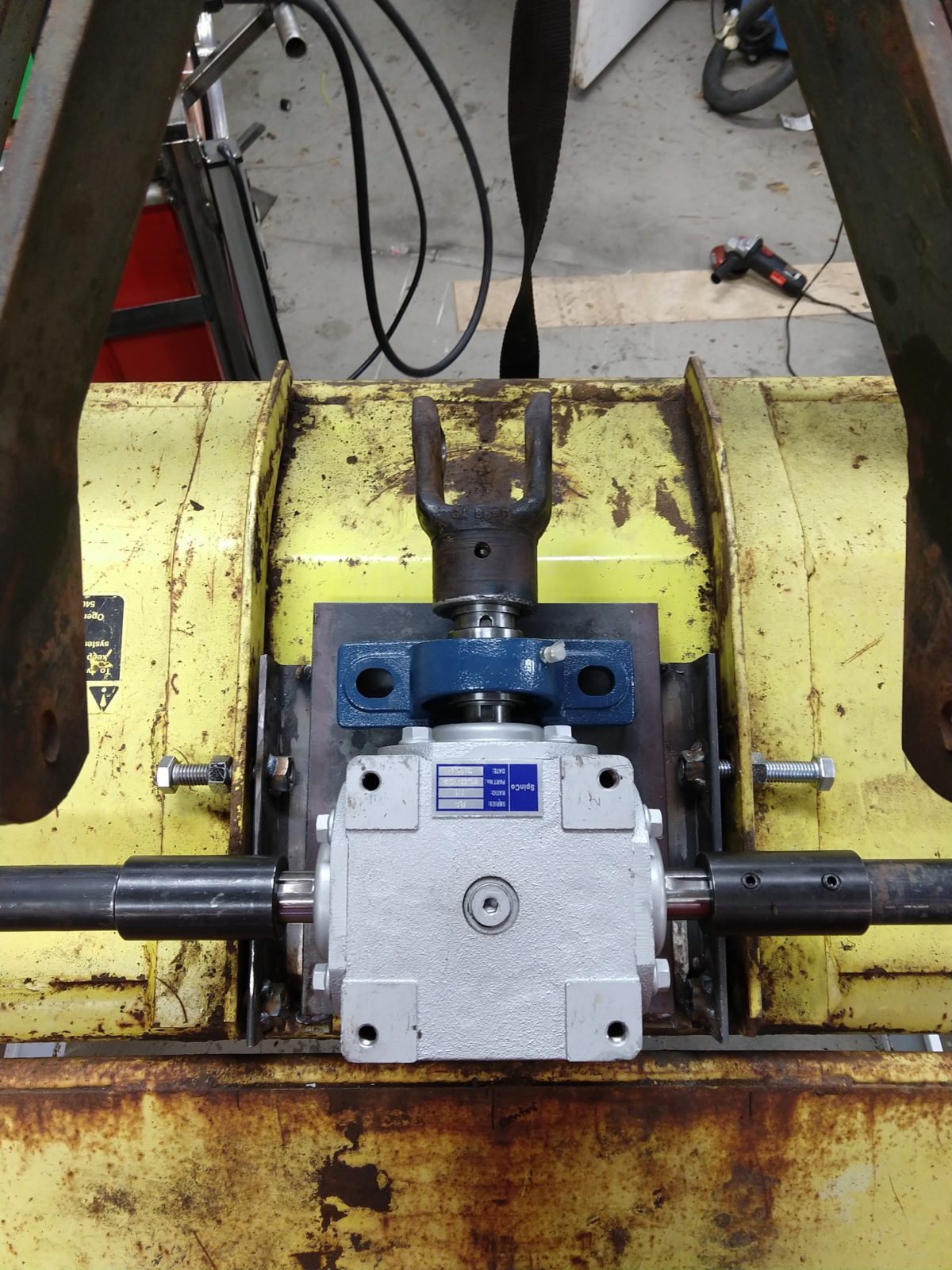

- Cut the shafts to remove the old gearbox

- Built up a mounting plate to hold it in place

- Shortened the original shafts, turned them down, and machined a keyway so I could use standard shaft couplers

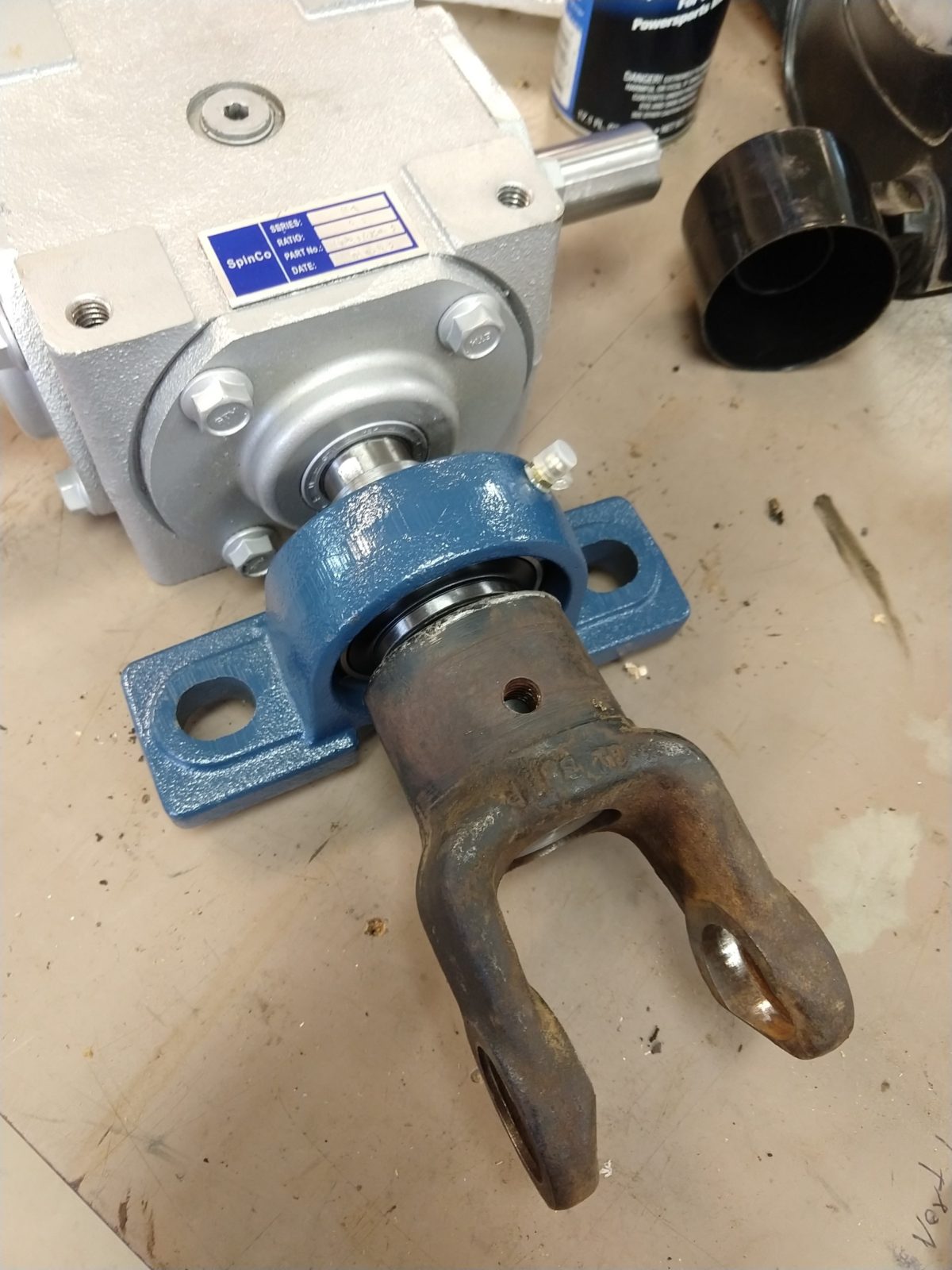

- Used a mounted bearing and made a shaft adapter to connect to the PTO shaft

- Cut down the original PTO shaft to a shorter length

- Laser cut new gaskets for the chain cases

The result: it works! I spent about what it costs to rent one of these three times, so in my mind I need to get three day’s use out of this to break even. Long term reliability is… who knows, but I am optimistic.