Author: admin

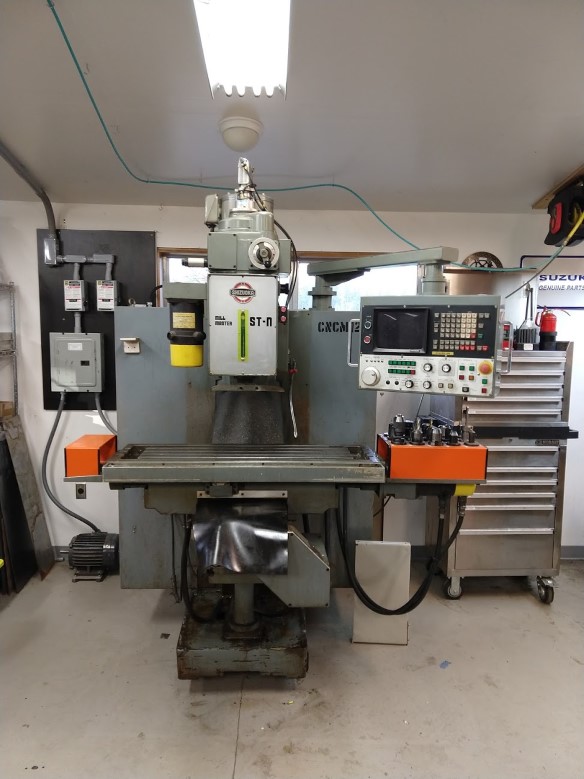

bookmark_borderNew To Me: Shizuoka ST-N CNC Mill

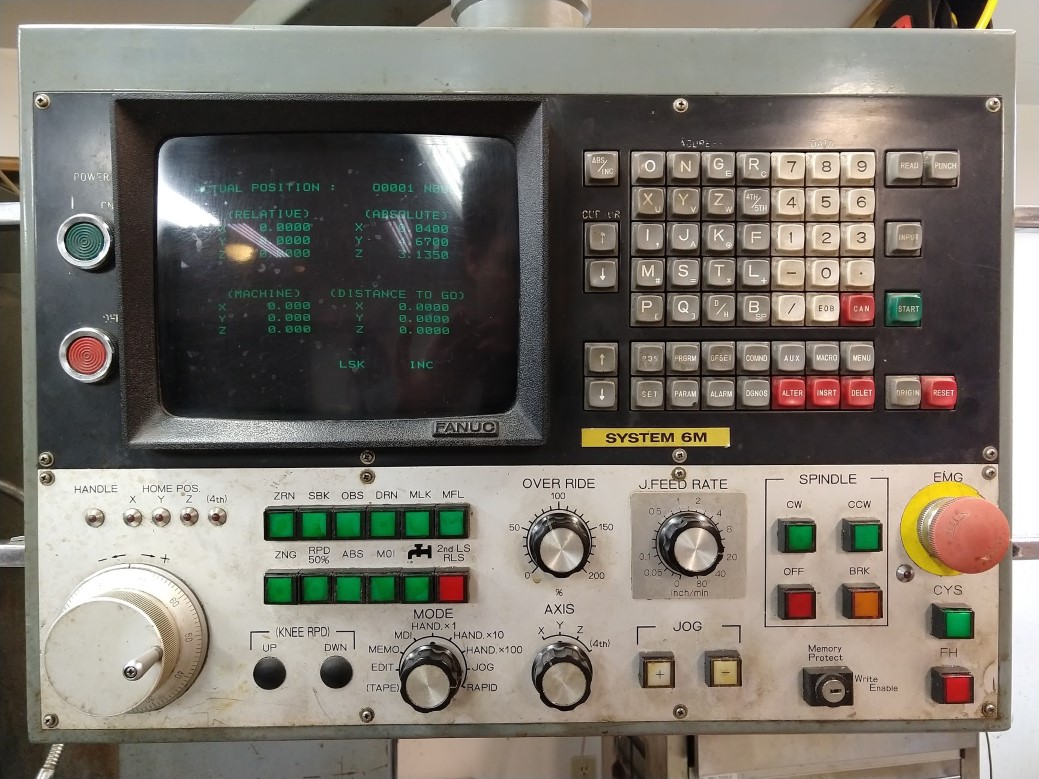

Got a new machine for the shop. This one is from 1984 and it’s in superb shape mechanically. Electrically it is has (had) one known issue: the X axis servo drive/velocity board would trip and cause a 401 alarm on the control intermittently (resolved this by removing a capacitor from the rotary phase converter to lower the voltage on the third leg, it was over 300 volts). It has a Fanuc 6MB control. I’m going to post some resources for this machine here just in case another person is ever looking, I had a tough time even finding a photo of this machine online.

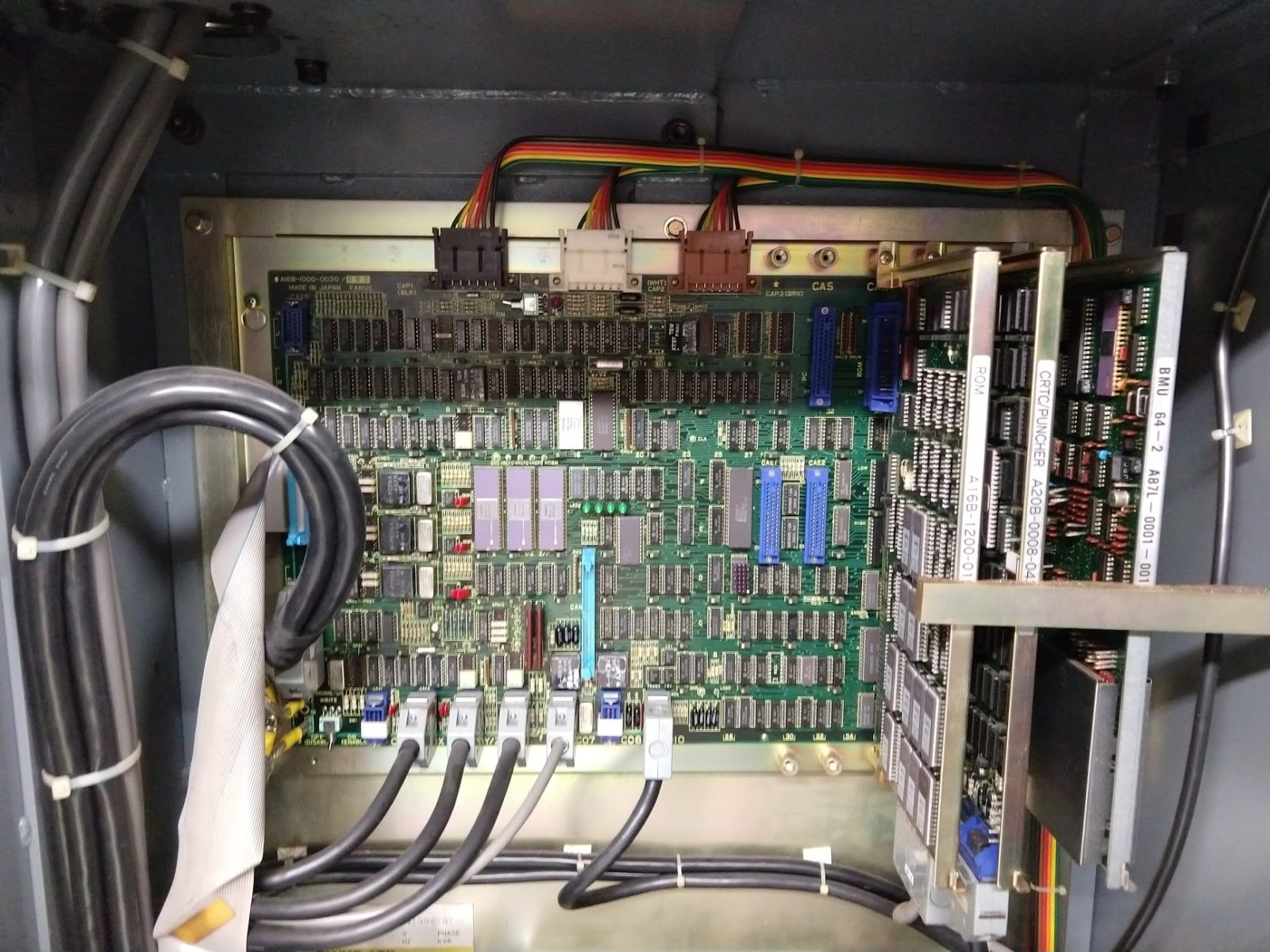

It is remarkable to me just how large the computer is that runs this control is, particularly with how limited the user interface is. This one still has a punched paper tape reader, but came with a BTR (behind the tape reader) unit that allows serial communication with a PC. Here is a photo of that:

The previous owner told me this came from a place in Australia, it’s a “Gateway V4 BTR” from Inspiration Systems. Information on this is also scarce online. It looks like this is the site for the company that produced it: http://www.softcncware.com/, but unfortunately they’re no longer in business. The wayback machine has some snapshots of the site which may have useful information on it. I am not going to mess with it until I need to, so far I have been able to load a program into memory from a PC with a USB serial adapter using DNC4U, but have not had success punching out the parameters, and haven’t tried drip-feeding a program yet.

I have the original manual for the machine from Shizuoka, a parts manual, as well as some very old “Data Sheet” pages that look like they’re from Fanuc and contain some special parameters for this machine – I have scanned them but the ink has faded to the point where it’s almost invisible, I’ll post those if I can recover something readable.

bookmark_borderJohn Deere Rototiller

I thought I would be smart and save some money and get a used tiller for the garden. Instead what I did was buy some scrap metal, then spend more time and money to turn it back into a tiller. The guy that was selling it described it as a “bad bearing”; I bet he was laughing as soon as I left. Luckily it was cheap.

To be fair to the guy, it did have a bad bearing… in the exploded gearbox. It had clearly been apart, so no doubt he knew what was up.

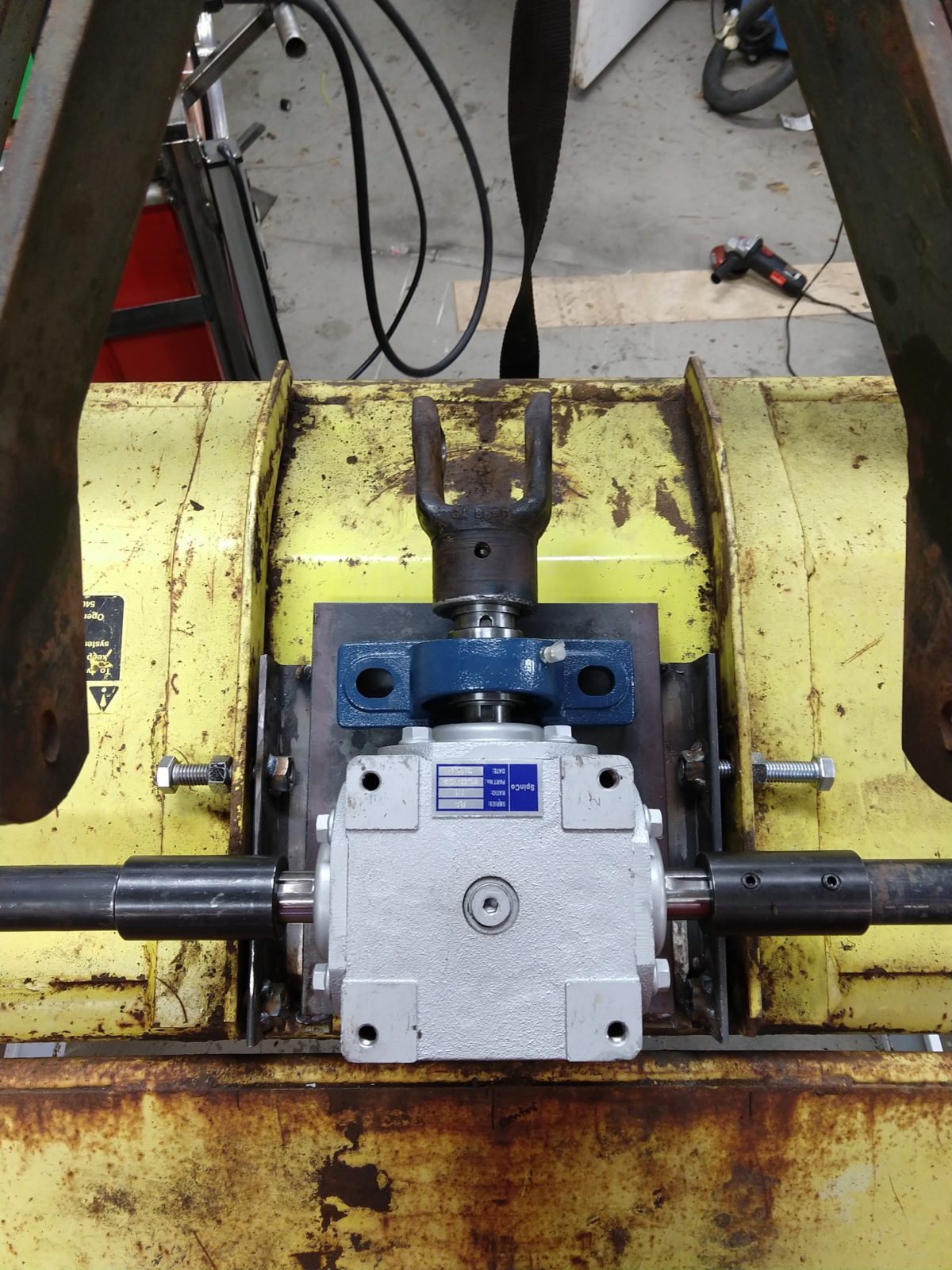

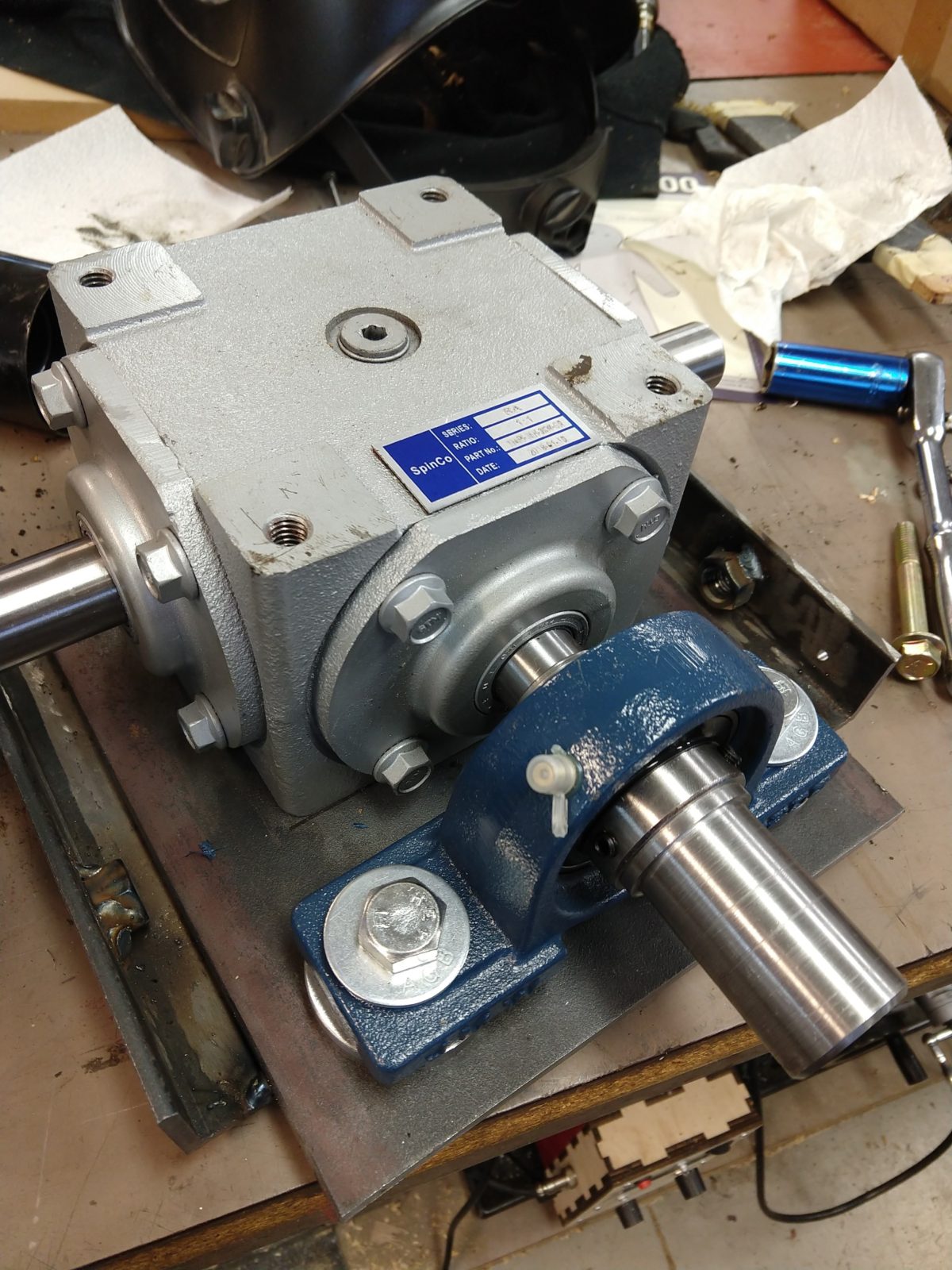

How do you fix that? This is a 40-series from the ’70’s, most parts are unavailable, and even worse, the shaft connecting the chains on the ends to the gearbox in the center is one solid piece. In order to disassemble it I would have to press that shaft almost three feet through the box to get it out. My answer was to replace the whole thing with the cheapest gearbox from China I could find on Ebay and adapt it to work in it’s place.

Here’s what I did:

- Cut the shafts to remove the old gearbox

- Built up a mounting plate to hold it in place

- Shortened the original shafts, turned them down, and machined a keyway so I could use standard shaft couplers

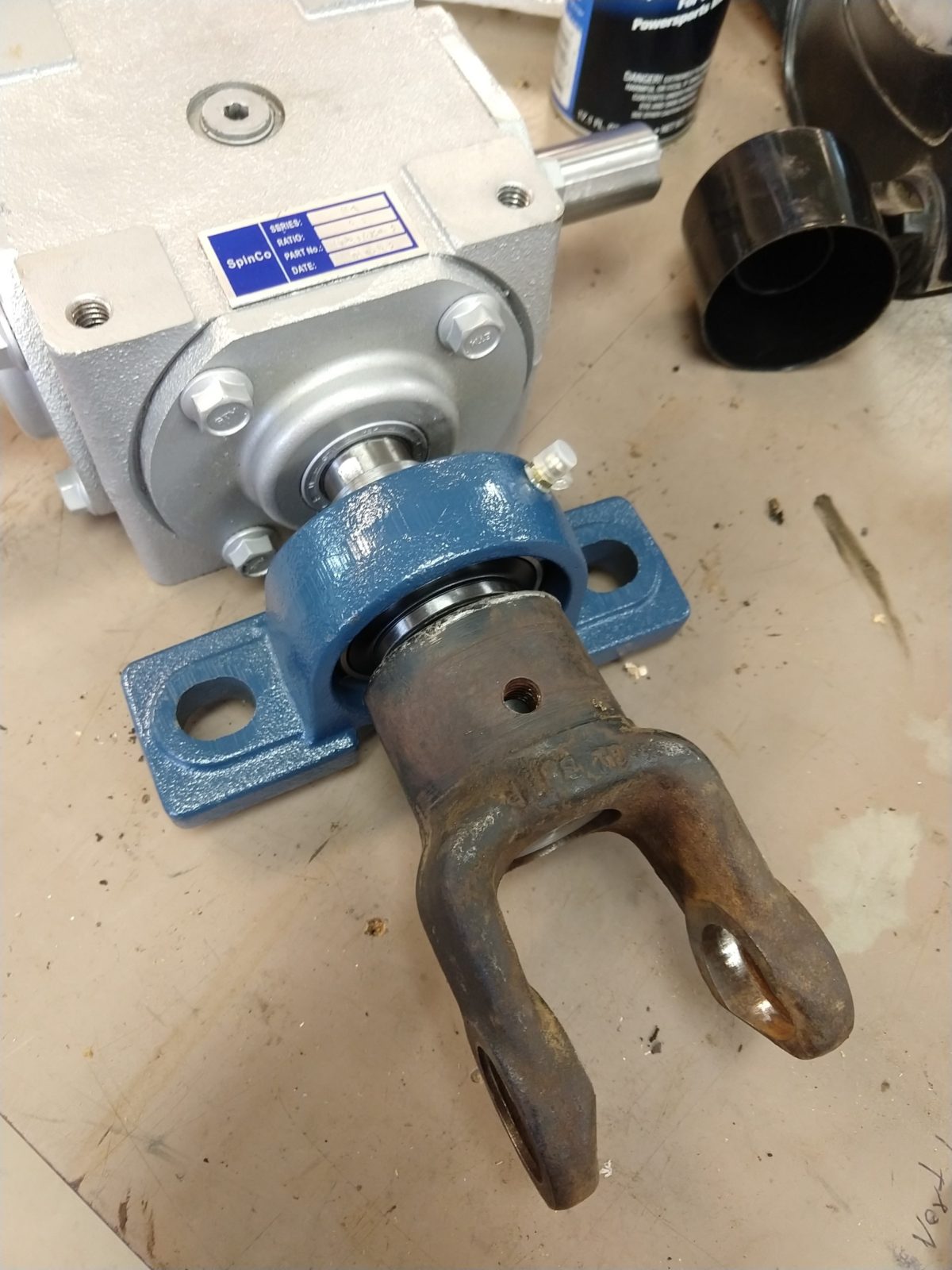

- Used a mounted bearing and made a shaft adapter to connect to the PTO shaft

- Cut down the original PTO shaft to a shorter length

- Laser cut new gaskets for the chain cases

The result: it works! I spent about what it costs to rent one of these three times, so in my mind I need to get three day’s use out of this to break even. Long term reliability is… who knows, but I am optimistic.

bookmark_borderOregon Wildfires

bookmark_borderBias Tape Maker – Work In Progress

Here’s a quick video of a machine I’m working on. It folds and irons a strip of fabric, similar to this machine: “Simplicity Bias Tape Maker“.

It’s functioning nicely, I just want to add an insulated handle to the top to prevent burns. The heating element is well insulated, the body doesn’t heat up with the exception of the two bolts that hold the floating top plate on… which will definitely burn you.

The temperature is variable and has closed loop control. Motor speed is also adjustable, in the video I have it running fairly slow. As you can see I’m not great with textiles, so my strip isn’t very consistent and has some big lumps at the seams.